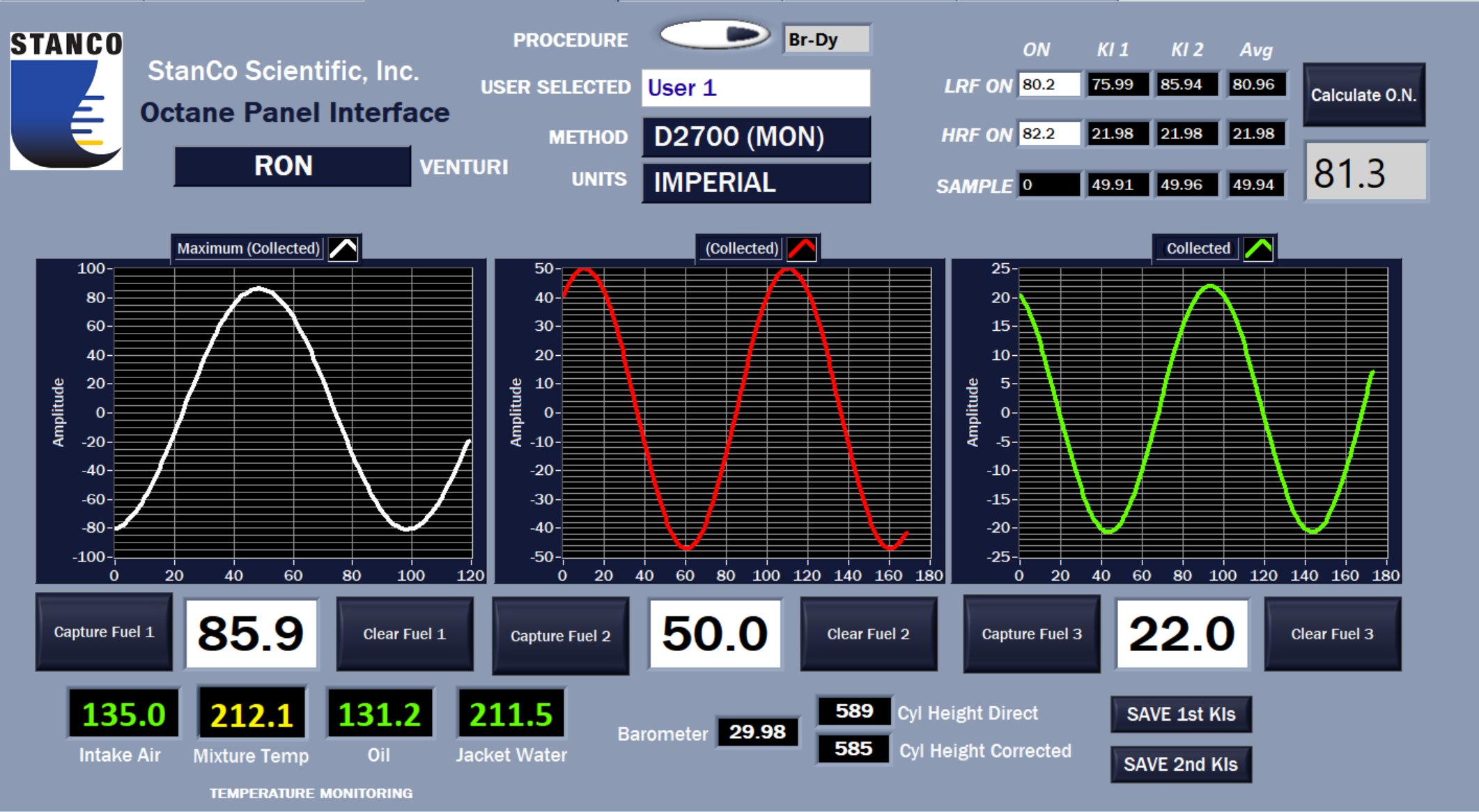

Octane Interface Panel

Description

Currently in development

Octane Interface Panel

Monitoring engine temperatures and pressures while recording data for Research and Motor Octane Number methods can be a challenge. Manually collecting and recording the data to complete an octane rating of a fuel is a process that can take time. And any mistakes can result in loss of time and money. The Octane Interface Panel takes a lot of the guesswork out of running a manual test without restraining an operator from performing the octane rating that they always have. This panel is an upgrade package for the Digital Control Panel.

Features:

- Designed for both D2699 and D2700 methods.

- Run both Bracketing – Dyanmic Fuel level and Compression Ratio procedures

- Calculation of bracketing using captured knock intensities according to the method’s requirements of Sample-LRF-HRF-Sample-HRF-LRF

- Lookup octane number based on current corrected digital count

- Constant monitoring of critical engine temperatures that are all displayed within the interface. Intelligent logic in place to give operators feedback about compliance with D2699 and D2700 requirements. All temperatures represented on a graphical interface for diagnostic purposes.

- Barometric pressure reference listed within the interface

- Run tests in either Imperial or SI units

- Observe the D-1 Pickup signal as the engine is running